Effect Of Temperature On Cement Grinding .

effect of temperature on cement grinding Overview. ... finishing cement mill temperature – Coal Surface Mining. Product List. grinding media ball screeners; ...

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

effect of temperature on cement grinding Overview. ... finishing cement mill temperature – Coal Surface Mining. Product List. grinding media ball screeners; ...

cement finish mill temperature control Grinding Mill China. cement finish mill temperature control. measure will be to vary the mill exit temperature of the product ...

The second method, we know the ventilation inside the mill + the quantity of water injected and we calculate the temperature of the cement at mill outlet.

Cement mill of high temperature harm 1. of cement mill itself is negative, such as high bearing temperature, lubrication to reduce, will make the cement mill ...

temprature control in cement mill. Cement mill Wikipedia, the free encyclopedia [edit]. ... How to control vertical roller mill temperature in cement ...

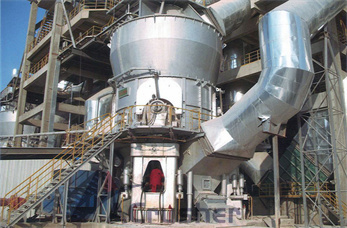

Cement Production Line Capacity: 50 t/d3000 t/d Application: Cement Plant Main Materials: Limestone,Clay ...

IJCAT International Journal of Computing and Technology, Volume 1, Issue 2, March 2014 ISSN : 2348 6090 47 Cement Mill Feeder Control System

Measuring Instruments for the cement industry Siemens offers a complete range for measuring relative instruments for example for pressure, temperature, flow and ...

effect of cement mill temperature on cement properties SBM. SBM is one of the biggest manufacturers in Aggregate Processing Machinery for the effect of cement mill ...

Cement mill Wikipedia. Ball mill application Ball mill grinding is a highly energy consuming process and the ECS/ProcessExpert Ball mill application is built to ...

gypsum grinding temperature upon early hydration of Portland cement ABSTRACT The temperature ... Gill Sensors Develops Oil Level Sensor for Cement Grinding Mill ...

‐ We know the ven la on of the mill, we want a temperature of the cement at mill outlet of 105°C. ‐ The mill heat ...

Cement ball mill is composed of six parts, such as feeding device, supporting device, rotary part, unloading device, driving device, lubrication devices and cooling ...

Cement Milling. Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls).

As everyone knows, cement mill outlet temperature high not only for the cement storage, quality and ball mill has serious effect.

Cement mill – Wikipedia, the free encyclopedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from ...

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL OPTIMISATION CASE STUDY Batra*, D. Bhaskara Rao** and Raju Goyal*** Holtec Consulting Private Ltd.,

Cement mill Wikipedia, the free encyclopedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from ...

Gulin machine in Cement raw materials processing plant, cement temperature in mill. Gulin provide the cement temperature in mill solution case for you.

cement mill temperature control – Cement mill Wikipedia, the free encyclopedia. A cement mill (or finish mill in North American usage) is the ...

1. Kiln Shell Temperature Detecting both hot and cold spots on a Cement Rotary Kiln. The early detection of hot or cold spots is vital to avoid costly maintenance or ...

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

The cement kiln system is designed ... to increase draught and thus obtain the higher temperature needed to make cement ... the fuel mill has to run ...

Engineering services, Cement Mill Water Spray . Internal water cooling in a cement mill serves to maintain the mill outlet temperature constant at ...

WhatsApp)

WhatsApp)