Bobs Red Mill Natural Foods

At bobs red mill, we say unprocessed is our processry our wholesome products shipped straight from the millree shipping on orders over 50.

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

At bobs red mill, we say unprocessed is our processry our wholesome products shipped straight from the millree shipping on orders over 50.

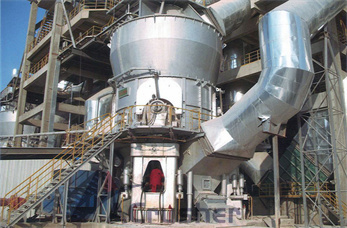

the board of gold miner beadell resources has approved a 27million upgrade of its tucano gold plant, in brazil, following a positive feasibility studyhe study considered the.

The gravity separation process create a comfortable loose layer and separation condition in virtue of integrating the media fluid and all kinds of mechanical force to obtain different density and diversity size particles process s the density of gold mineral is much bigger than gangue mineral, for the gold mine which has gold particles should use gravity separation process is a high.

Miners who excavate and extract semiweathered gold ore and take this for processing at custom milling centers here are about 3,000 to 5,000 people involved in this activityillers who work in the milling centers where the ore is milled and concentrated for the minershere are probably about 1,000 to 2,000 people in 70 milling centers.

Hammer mill vs ring granulator for coal silica shaking table in lima peru sand making flows manganese ore beneficiation equipment what is the cost for robo sand crusher 2 2013 newest and best performance stone impact crusher prakash gears gears manufacturer coal mining in jaintia hillscoal mining in jericho.

12 things you should know about diamond drill bits 15th september 2017 you can then grind away the edges with a diamond burr so that your bead sits flush in the holethey are very popular with bead artists to increase the size of holes in beads and are ideal for increasing the size of holes in pearls.

mine your own ferromagnetic metal slivers tired of paying for that ferrous metal scraps that you mostly use for entertainment purposes among other thingsell heres how you can make your own ferrous metal scraps that you can use for such things as ferrofluid, science classesentertainm.

coppermolybdenum orehe figure above is a simplified flow sheet showing the basic steps involved in a copper mill producing the byproduct molybdenumhe crushed copper ore containing, for example, 0 cu and 05 mo is fed to the grinding circuit where water is added and the ore is ground to the proper size.

Therefore, system and milling dynamics the balls tumble within tubular mills, they provide a grinding are interrelatednside the ball mill, the particles are hit action and forces of attrition, all of which result in further by mechanical charge of great power which leads to large reduction of the size.

ball milling and classification circuit, with a final grind size of p80 of 180 m magnetic separation circuit, removing waste magnetic material before flotation magnetic separation circuit, removing waste magnetic material on the dms sinks final concentrate.

Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted materialhe milling process requires a milling machine, workpiece, fixture, and cutterhe workpiece is a piece of preshaped material that is secured to the fixture, which itself is attached.

Mineral processing plant design and optimisation ball mill psd control controlling particle size distribution of ball mill benefits improves product quality by maintaining psd and maximizing particle recovery stabilizes ball mill operation, which will optimize operating points,.

Pyrite mining process equipmentur company is a profession manufacturer of complete set of pyrite mineral dressing plant which includes ball mill, crusher, magnetic separator, flotation machine, screener, spiral chute, shaking table and washing equipmentaw crusher in pyrite mineral dressing process.

Upon the size of the ball quenching simulation of steel grinding balls 5most current models do not account for varying conditions inside the mill and their use is restricted to.

conventional grinding using a rod mill or ball mill will also be used, or some combination, to grind the ore to fine powder micron size using rods, balls, with the ore in the sag mill to assist.

How to choose the right gypsum mining process machine supplier with the wide application of gypsum mining process machines in the industrial field, the number of gypsum mining process machine suppliers in the market has also increased, so whether the gypsum mining process machine of many suppliers can meet the test and approval of.

and i think there were 14 ball mills and you had to do your own lubrication of the babbot bearings and it was just an exciting time and there were only 4 people in the millnterview subject will trythal section mill stages up in the upper part of the mill, trains coming out from the 4100 portal would put the coarse ore into five coarse ore.

laboratory sample preparation 12introduction should be covered before they are movedolid samples are often ground to a fine particle size before they are fused or wet ashed to increase the surface area and speed up the reaction between the sample and the fluxing agent or.

an alternate route is available if you really cant get that much iron but you are willing to spend 5 extra redstone dusts, you can save yourself 4 iron ore and a tin oreayo now that youre safe at your base, smelt exactly 27 iron ore, 3 copper ore and 3 tin oreor the alternate route smelt exactly 19 iron ore, and 3 copper ore.

orefinders resources incsxvorx announced an average of 93 gold recovery at an average grind size of p80 of 65m, during preliminary metallurgical scoping.

WhatsApp)

WhatsApp)